| Pulling And Lifting Machine |

|

|

|

|

| Multipurpose, Portable, Universal, Gearless, Hand operated Pulling and Lifting machine, Supplied complete with telescopic, operating handle and standard Length of super flex steel fibre-mixed core wire-rope fitted with Hook or Shackle at one end and fused and tapered at the other end. |

|

| Pulling & Lifting Machines Hy-Tack XL Series 2005 |

|

|

Technical Specifications

|

HT-7

|

HT-13

|

HT-20

|

HT-35

|

HT-58

|

|

Dimensions (Approx.)

|

515 x 265 x 110

|

600 x 360 x 155

|

620 x 360 x 155

|

720 x 400 x 160

|

810 x 465 x 190

|

|

Capacity (SWL) (kgs) Lifting, Pulling

|

750, 1250

|

1600, 2600

|

2000, 3000

|

3200, 5200

|

5000, 8000

|

|

Length of Telescopic operating handle (Approx.)

|

54/72 cm

|

66/104 cm

|

70/130 cm

|

79/118 cm

|

120/145 cm

|

|

Effort at full load (Approx.) kgs

|

40

|

50

|

50

|

60

|

70

|

|

Rope travel per Return stroke (Approx.) mm

|

40

|

55

|

50

|

36

|

30

|

|

Diameter of wire Rope (mm)

|

8.0

|

11.3

|

12.0

|

16.3

|

20.0

|

|

Standard Length with Each machine (meters)

|

10

|

20

|

20

|

10

|

10

|

|

breaking Load of wire rope (Approx.)

|

4.5 Tons

|

9.0 Tons

|

10.0 Tons

|

18.0 Tons

|

24.0 Tons

|

|

|

| Exclusive Features |

|

Casing:

|

Made from CRC sheet (Galvanized) or Graded Aluminium for

light weight a high factor of safety. |

|

Jaw:

|

Made from Special Alloy Steel, Accurately Machined, so as

to avoid slippage of wire rope. |

|

Jaw Limits:

|

Are made from special steel & heat treated for greater strength. |

|

Hooks / D-shackles:

|

Fitted with Alloy steel Forged Hooks or D-shackle to make

it feasible to be able to fit it at any place. |

|

Wore Ropes:

|

Super flex Steel Fiber -mixed are, manufactured as IS. 226. |

|

|

| Accepted & Widely used by |

- Railways

- Mines and Quarries

- Navigator

- Electricity Board???s

- Dockyards

- Road Transports

- Heavy Industries etc.

|

|

|

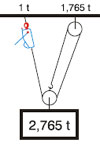

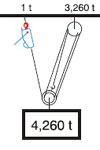

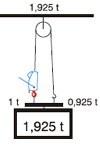

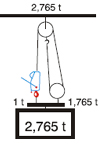

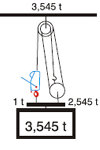

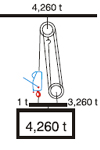

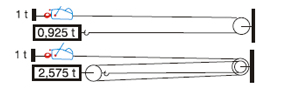

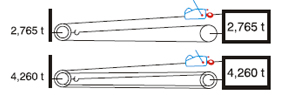

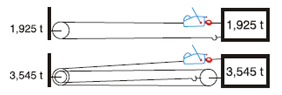

| Increase of Pulling and Lifting Power: |

|

| Lifting - machine anchored above load |

|

|

|

| Lifting - machine anchored to load |

|

|

|

| Lifting - machine anchored at ground level |

|

|

|

| Pulling - Case No. 1 |

|

|

|

| Pulling - Case No. 2 |

|

|

|

| Pulling - machine attached to load |

|

|

|

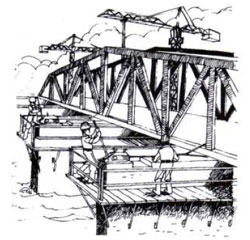

| For General Work on Site: |

|

| Many applications for bridge building such as: |

|

Moving of support for concrete forms

Support of under-slung formwork

Pulling per-cost concrete beams, etc,

|

|

|

|

|

Fig 4.1

|

Fig 4.2

|

|

|

|

|

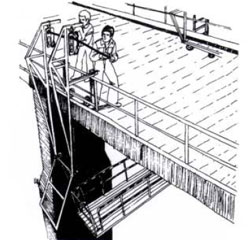

Fig 4.3

|

Fig 4.4

|

|

|

| Railway uses ( buildings and permanent way): |

- Siting and joining of rails (fig.4.2)

- Assembling, dismantling or maintenance of points and crossing with smaller teams and without the risk of distortion of the track

- Replacement of electric cable in gutters or under the track

- Lifting sections of track for replacing ballast and sleepers

- Cable tnsioning for points and signals

- Lifting (or removal) of pylons and signals (fig. 4.1)

- Maintenance and tensioning of catenaries, etc.

|

| Operations: |

- Emergency operation of frozen points

- Re-railing work

- Replacing friction buffer stops

- Giding & lifting rails

- Loading trucks on lorries in case of changing track (railway tracks of different gauge)

- Shunting or unloading wagons in small stations, etc.

- Removing crash wreckage

- Equipment of plate-layer special trucks (welded rails 215m. long.)

- Replacing ballasts with gantry cranes

- Checking compression and rod-system of steam engine

- Equipment for rescue carriage and trains

|

| Pipe laying and joining. |

- Special rigs have been constructed using Pulling Lifting Machines for the jobs of both laying large diameter concrete pipes and for pulling them together for jointing (fig. 2.1 & 2.2)

- Cleaning out pipes and sewers

- Pulling a carriage through steel pipelines for welding, x-ray inspection of welding joints concrete coating, etc.

- Positioning of pipes for welding (fig.2.3)

- Under water pipeslines assembly (fig.2.4)

- pulling pipes through tunnels (fig.2.5)

|

|

|

fig. 2.1

|

|

|

|

|

|

Fig. 2.2

|

Fig 2.3

|

|

|

|

|

Fig 2.4

|

Fig 2.5

|

|

|

| For Shipbuilding and Marine Engineering |

- Handling large plates

- Erecting masts and booms

- Suspending welders', riveters' and painters' cradles (fig3.3)

- Centralizing ship in dry dock (fig.3.1)

- Lifting engine covers

- Installing engines (fig.3.4)

- Pulling through tail shafts

- Installing and removing propellers

- Emergency operation of davits

- Opening hatches

- Handling hold covers (Mc Gregor system)

- Lifting small boats out of the water (fig 3.5)

- Dragging boats ashore

- Pulling together pushers and barges of floating merchandise trains (fig.3.2)

|

|

|

fig. 3.1

|

|

|

|

|

|

Fig. 3.2

|

Fig 3.3

|

|

|

|

|

Fig 3.4

|

Fig 3.5

|

|

|

| Trucks |

|

|

Fig 1.1

|

|

|

Fig 1.2

|

|

- Debogging of trucks (fig1.1)

- Tensioning heavy and bulk loads on trucks (fig.1.2)

- Loading onto trucks (fig.1.3)

|

| Rigging and maintenance of construction euipment |

- Changing and tensioning tracks and conveyor belts

- Changing and tensioning excavator ropes (fig1.4)

- Handling excavator jibs

- Erecting tower cranes (fig 1.5)

|

| Miscellaneous |

- Removal of a site cabin (fig 1.6)

- Tensioning of safety-nets on construction sites (fig1.7)

|

| Fixing heavy girders |

- When a girder is lowered in position by a crane, it may not be in a suitable position for bolt hole line-up, A Pulling Lifting Machine can be used to pull it until holes line-up.

|

| Erecting steel silos |

- Assemble at ground level, then lift section after section (fig.1.8 & 1.9)

|

|

|

|

|

|

Fig. 1.3

|

Fig 1.4

|

|

|

|

|

Fig 1.5

|

Fig 1.6

|

|

|

|

|

Fig 1.7

|

Fig 1.8

|

|

|

|

|

|

|

Fig 1.9

|

|

|