Wire Rope Slings

|

|

|

||||||

|

|

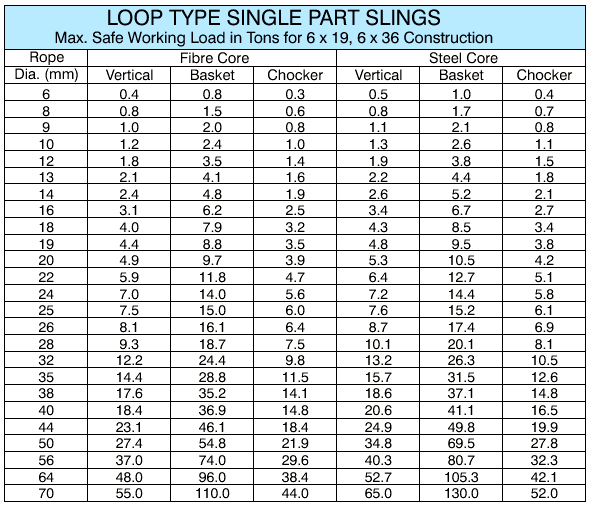

| Loop Type Single Part Slings | ||||

|

||||

|

||||

|

||||

|

||||

| Factor Of Safety 5:1 Tensile Strength: 1770/1960 N/mm2 | ||||

|

||||

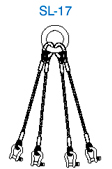

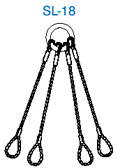

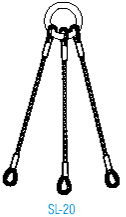

| Multi Leg Slings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Factor Of Safety 5:1 Tensile Strength: 1770 / 1960 N / mm2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Wire Rope Nets For Cargo Lifting | ||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

| Grommet Slings | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Application for Grommat | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Endless Slings |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Butt Splice | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The two ends of the rope should be joined together by two five ???tuck splices. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Number of Tucks | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The splices shall be tucked three times the full size of strand, a fourth time with the strand each reduced to half the original number and a fifth with the strands each further reduced to one third the original number. The heart strand is to be rowed in during tucking so that a double heart is produced for at least the length of the first three tucks in both directions. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Method of Tucking | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The Tucks of the Splice shall be made over one strand and under one strand against the lay of the rope. The heart strand of the rope shall not be removed when the strands are opened out for tucking, but may be cut to a suitable length. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Finishing | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The ends of the splice in way of the twisted ??? off ends of wire that is between the end and the third tuck shall be tightly served with seizing wire, after parcelling with canvas, Hessian or wax paper. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flemish Slings | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

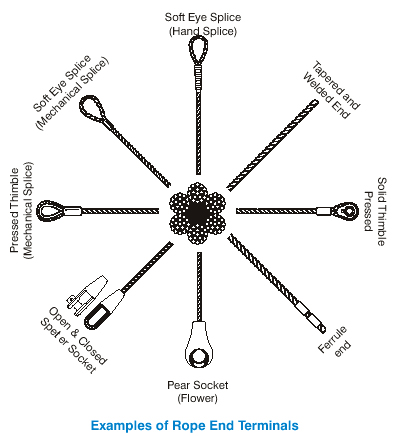

| Wire Rope Press ???Grip Sling Are Economical ???Safer And Easier To Work With |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Three slings you can count on high strength efficiency on all eye splices.they are tapered and completely sealed with at both end to avoid snagging on loads. these ferrules completely cover all strands and locks them securely into place. there are no opening or rough projection to catch on hands. Rope slings with special pressed ???on metal ferrules are easier to work with.

Slings are made from 6x19 wire rope and from 6x37 wire rope. We recommended use of 6x19 construction. Upto 1 ?????:6x37or large slings. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Note: Standred sleeves are recommended for use with 6x19 or 6x37,IPS or EIF RRL,FC or IWRC wire rope. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||